Use and maintenance of ground drill

Use and maintenance of ground drill

With the popularity of garden machinery and the development of modern agriculture, the ground drill is sold in the general garden machinery shop, and it is simple to use, easy to maintain, and has a relatively high work efficiency, and it is well received by agricultural personnel.

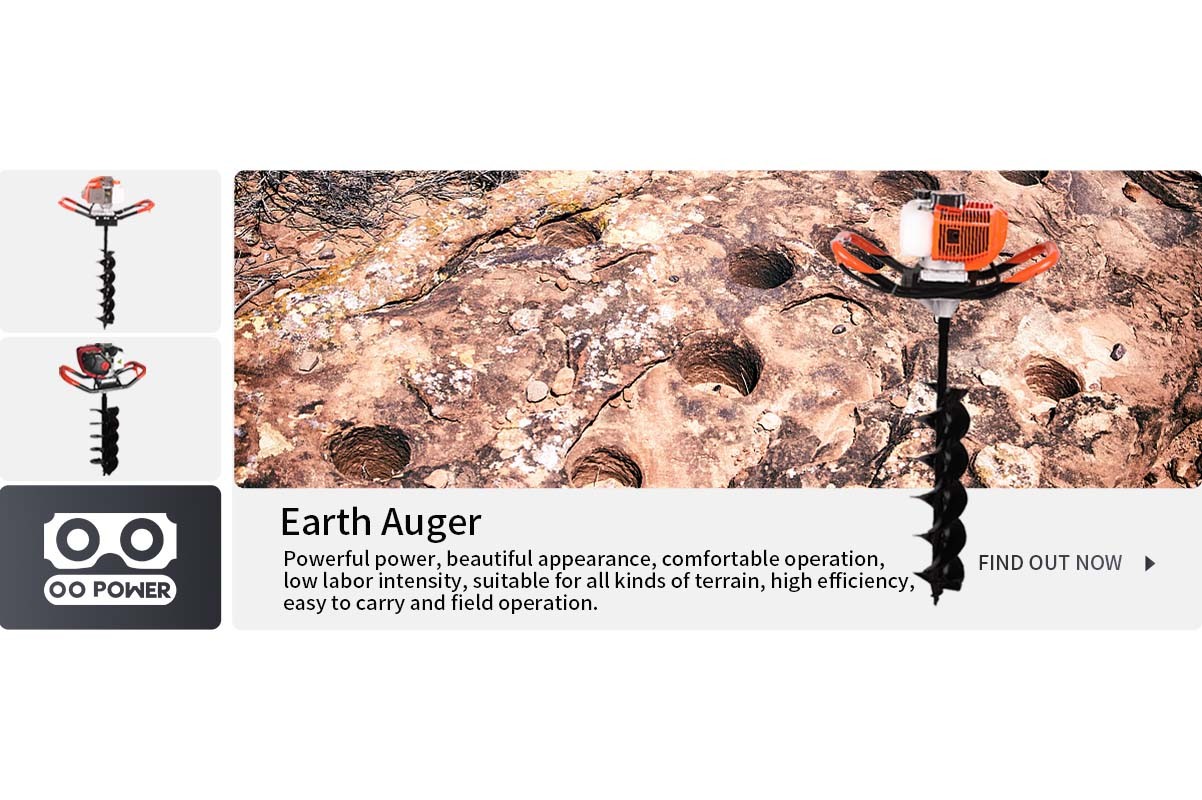

Ground drilling is not only widely used in the sloping land, sandy land and hard land in the nursery stock landscaping project, but also used in planting pits and digging the periphery of big trees. It is also used in the fence buried pile digging, fruit trees and trees fertilization digging. The ground drilling operation is no less than 80 pits per hour. According to the calculation of working 8 hours a day, 640 pits can be dug, which is more than 30 times that of manual work. Ground drilling truly realize the process of automatic operation, so that people from the heavy physical labor liberation. The drilling power of the drill is powerful, with the advantages of beautiful appearance, comfortable operation, low labor intensity, adapt to various terrain, high efficiency, easy to carry and field operation.

Common drilling styles include nest drilling and vertical drilling. Vertical ground drilling also has the difference between the number of users, such as single and double.

I. The Type of Ground Drilling Bit:

1. The diameter of 60/80/100/120/150/200/250/300/400 mm drill bit, length 80 cm;

2. Extra alloy centering drill bits are available;

3. The excavation rate of double spiral blade drill is better, and single-leaf drill is suitable for wet soil, depending on the use environment;

4. Extended length drills, special order required, commonly 80cm;

5. Luxury drill: centering drill blade can be replaced (with screws, a pair of blade); common drill blade materials are: manganese steel, alloy, tungsten steel.

II. Common Sense of Use and Maintenance

1. General Safety Measures

(1) Prohibited for indoor use.

(2) Keep a safe distance of not less than 1m from flammable objects.

(3) When refueling, smoking is prohibited, the engine must be stopped, and petrol spillage is prohibited.

(4) Work with protective goggles and protective facilities, do not use without protective cover.

(5) Keep hands and feet away from the machine before turning and stopping.

2. Check Before Operation

(1) Fuel level. Check the fuel surface from the outside of the tank, if the fuel surface is low, add fuel to the upper limit, the fuel is made of unleaded petrol and two-stroke oil 25-30:1 mix ratio, never use pure petrol and petrol containing impurities;

(2) Air Filter. Check the air filter element for dirt. If any dirt is found it should be cleaned;

(3) Throttle cable. Check the free clearance of the throttle steel cable at the end, and check the throttle handle for smooth operation.

(4) Blades. Check for loose blade mounting nuts, tighten nuts if required. Check blades for cracks, nicks, bends, and wear, replace if needed;

(5) Cutter guard. Check guards for looseness and tighten guard safety bolts if required. Check guards for damage and replace if required.

3. The Correct Use of Ground Brill

(1) Start of engine

1) Preparation Before Startup

Check the engine oil level. Place the engine in a horizontal position and clean around the oil filler neck. Remove the dipstick, wipe off the oil with a clean cloth, and reinsert it into the oil pan. Remove the dipstick again and check the oil level. If the oil level is too low, add oil, all the way to the upper mark in the dipstick.

Note:

① A low oil level can cause engine failure. However, the oil level should not exceed the upper scale. Excessive oil will cause power loss and make the machine smoke.

② Check that the air filter element is not clogged and always maintain it if necessary. Never use an engine without an air filter, otherwise, it will accelerate the wear and tear of the engine.

③ Check the fuel level in the fuel tank and always use pure petrol..

2) Start and Turn Off the Engine

When the engine is started, the fuel switch should be triggered to the open position and the damper switch should be triggered to the damper position.

Note:

① If the engine is warm or the air temperature is high, do not use the damper, but trigger the throttle position to the fast position to start.

② When starting, pull the starter rope gently outward until you feel resistance, then pull quickly, move the throttle to the stop position, and then trigger the fuel switch to off position.

(2) Problems to Pay Attention to When Using the Punching Machine

1) For the lawn that needs to be drilled, remove stones, wires and other items that may cause dangerous accidents before starting work.

2) Spray the lawn with water before drilling in order to achieve the ideal drilling effect.

3) Mark the nozzles, wires and other objects on the lawn that need to be avoided in order to prevent them from being touched during the work.

4) Keep children away from the punch.

5) Check the gearbox oil level before work.

6) Keep the rear wheels in the lowest position.

7) Make sure the belt tension clutch retracts and releases itself..

8) Start the engine and adjust the throttle to the operator's normal walking speed so that the operator can always control the machine comfortably.

9) Do not work on slopes with a slope greater than 30 degrees.

10) Do not place hands or feet next to moving or rotating parts while the machine is in operation.

11) Do not open the transmission guard device during operation.

12) Do not change the configuration of the lawn punching machine without authorization.

13) Shall not be used for other ground operations except lawn

4. Maintenance

(1) Spark plug. Disassemble the spark plug, clean the carbon deposits, and measure the (electrode) gap between 0.6-0.7mm;

(2) Service fuel filter and clean fuel tank. Pour out the engine fuel, remove the filter and clean it gently; remove the water and dirt attached to the fuel tank;.

(3) Heat sink. Check the heat sink through the engine hood to see if it is dirty, and clean it if it is;

(4) Fuel Line. Check the fuel pipe, if it is aging or leaking oil should be replaced in time.

(5) Blades. Replace the blades in time.

HUSTIL is a professional custom garden tool manufacturer. We provide a full range of accessories search queries, garden tool accessories replacement, and after-sales service for our VIP users. After more than 10 years of strict screening, we now have more than 300 mature supply chain factories for production; at the same time, we are a 21-year experienced accessories manufacturer.